Integrated Ionization on the FFU

Since Ionization’s function is to make the air conductive, eliminating static charges on insulators below, it is only natural for the ionization to be integrated with the airflow of a Fan Filter Unit (FFU). TES-Clean Air Systems has been a contracted master representative of Simco-Ion for over 20 years, and as such is in a perfect position to deliver you a complete solution on your next critical project. Having the ionizing Aerobar powered/controlled by, and attached to the Fan Filter Unit (FFU) removes one more thing from your plate, allowing you time for other details of your design.

Since Ionization’s function is to make the air conductive, eliminating static charges on insulators below, it is only natural for the ionization to be integrated with the airflow of a Fan Filter Unit (FFU). TES-Clean Air Systems has been a contracted master representative of Simco-Ion for over 20 years, and as such is in a perfect position to deliver you a complete solution on your next critical project. Having the ionizing Aerobar powered/controlled by, and attached to the Fan Filter Unit (FFU) removes one more thing from your plate, allowing you time for other details of your design.

The “dirty secret” in particle controlled environments is that it is not how many particle that are in an environment (ISO1 versus ISO 2 and etc.) but how many particles end up on your wafer/mask/plate. And the “X” factor in this formula is how static charges draw the particles in the clean zone to the wafer/mask/plate. The fix? Simco-Ion, with their best in class line of Modulated Pulse AeroBars. The MP bars are the technologically advanced and ultra-clean line of ion bars ever produced being ISO 14644 class 1 for 0.1 micron and even ISO 14644 class 12 at 0.01 micron, when run at 45-50% output voltage settings.

Having been a Simco-ion channel partner for over 30 years, TES is in the perfect position to provide the correct size and number of Simco-Ion MP bars fully integrated into the FFU to meet your discharge specification. Check out our story, below here.

One of our main jobs here at TES-Clean Air Systems is to allow you to shorten your supply chain by including additional features in the FFU that transfers tasks from your “to do” list to ours.

In this case full specification of and integrations of the ionizer.

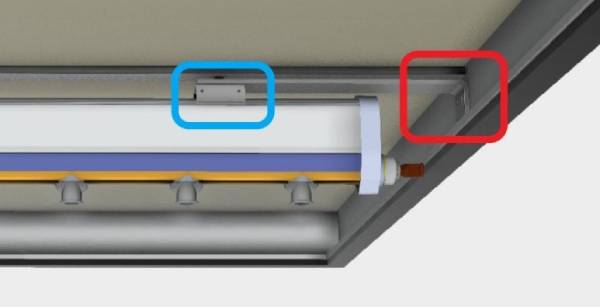

- The first thing that has to be addressed is physically having the bar mount become part of the FFU. For this we have our filter partner, AAF International, make the FFUs filter with an extended section of frame below the filter media/face screen. To allow for a bare metal surface for Airflotek to attach Stainless Steel “L” brackets the filter is constructed so that the potting material (Glue) that fixes the media to the filter frame is restricted from flowing into the area where the “L” brackets will attach.

- With the FFU “L” bracket installed (in red) the ionizer mounting bracket (in blue) is then installed and the MP AeroBar is snapped into place.

- Ok, so now the bar is mounted. How about powering the bar?

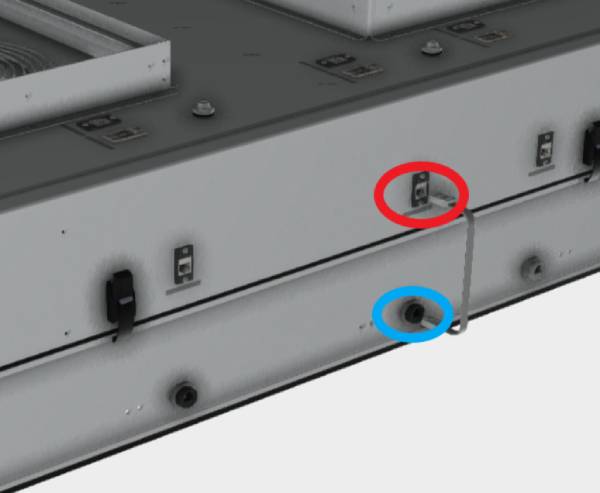

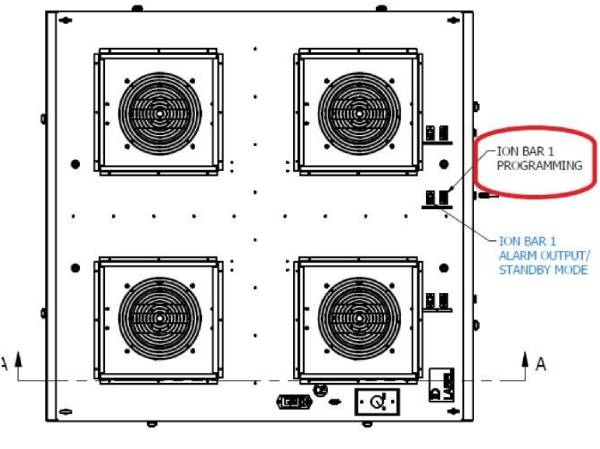

Using the “AeroBar MP” software from Simco-Ion, plug into the programming port. From here all settings and adjustments to the AeroBar are made.

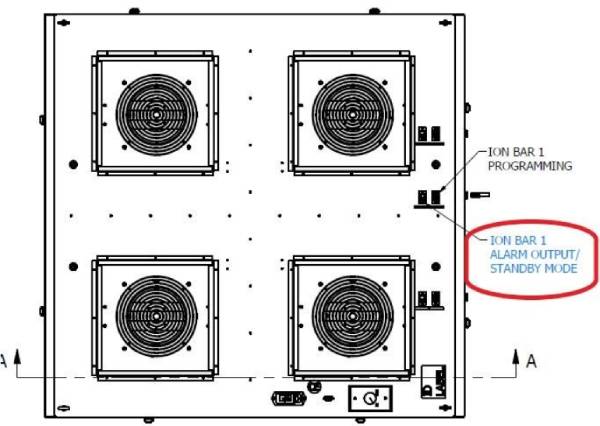

- By wiring your tool to the “alarm output/standby” connector your tool will see the status of the bar (OK versus alarm conditions). Additionally you can put the bar into “standby mode” for testing. When in “standby mode” the Aerobar is powered and remains warmed up and ready to go-but with no ion output.

We currently have a large group of customers with custom engineered FFUs with the 5225 generation of Aerobar integrated into the FFU design. Since that older generation of Aerobar’s performance has been eclipsed in utility, effectiveness, and cleanliness by the 5635 MP series of Aerobars we now offer an upgrade path for our existing customers. It is literally as simple as bolting the 5635 MP upgrade module in place where the 5225’s Interface Module was and snap a 5635 MP bar in where the 5225 bar was. Upgrade complete.

Additional PDF Resources

- “Expandable Ions”: How to ensure you will meet a discharge specification

- Fully integrating Simco-ion Modulated Pulse (MP) Bar(s) into the FFU, the details

- 5635 MP Aerobar Upgrade Module