Temperature and particle controls rooms for FPD production

Gen 10 FPD (2850 mm X 3050 mm) is in full production mode, with Gen 10.5 and 11 on the way. The environments required to do the processing requires both lower ISO class clean room classifications and tighter temperature controls every day.

TES-Clean Air Systems specializes in being a full service provider of these environments, from small test chambers to much larger rooms requiring temperature control as tight as +/-0.004 deg C. Allow us to meet your specification for your tool enclosure so you can focus on the real work at hand, dialing in your process.

Most often the environment takes one of two forms:

1) The complete modular room with ECU, connected by custom designed ducting, designed to your specification.

With our custom engineered Environmental Control Units (ECU) and we can provide a stable temperature and humidity environment to meet the most demanding specifications.

With our custom engineered Environmental Control Units (ECU) and we can provide a stable temperature and humidity environment to meet the most demanding specifications.

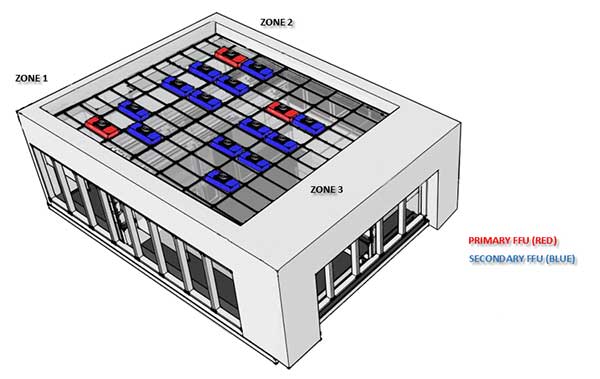

2) Where the process and facility are integrated:

In this case, where we are the #1 supplier of application specific Fan Filters (FFUs) in the world, we can provide blocks of FFUs to cover the ceiling of the environmental chamber, yielding multiple “zones” of coverage.